3A = Art et Acoustique Appliquée = abbreviation

3A Catalogue - 1977

Photo of a 1980 catalogue from 3A - Courtesy of Jean-Paul GUY

Link: radiomuseum

Summary: 3a Art et Acoustique Appliquée S.A., Chemin du Pont Romain, Z.I. 06600 Antibes.

Art et Acoustique Appliquee was founded in the 1970s by Daniel Dehay. They manufactured hifi speaker systems.

History: This manufacturer was suggested by Franz Scharner.

Так как обе колонки из разных партий (свидетельство далеких #180379, 146284 серийников и разница в фильтрах, а так же разная конструкция бассовиков в раене срдечников около катушек) проведены следующие работы:

- фильтра подогнаны под общий знаменатель на прекрасных комплектующих (ТОЛЬКО ВИНТАЖНЫХ, ТОЛЬКО NOS [новых и прогретых!!!!])

- заменены подвесы ППУ на качественные, такие же по жесткости (но из-за разницы в конструктиве НЧ динамиков у них раные показания по низу [смотрите наклейки на каждом бассовике] - эта разница в принципе ощутима на дальней зоне и при высокой громкости, близкой к пиковой нагрузке), работы проводились у лучшего мастера в РБ (никаких подтеков, никакой ассиметрии и прочей белиберды)

- выровнен один из куполов СЧ (приехала ко мне пара уже с данным дефектом)

- заменены терминалы обоих колонок на задних стенках (оригинальные были пружинного типа и добиты прошлым владельцем)

- усилительная часть собрана на рассыпухе (ТОТ САМЫЙ МОМЕНТ когда хочется сказать: "Молодцы ФРАНЦУЗЫ, покорили меня")

Маленький нюанс из разряда французской разработки:

- мониторы являются активными, но! встроенный усилитель изначально однополосный и работает только как усилитель низкой частоты!!! то есть для общего включения вам необходим внешний усилитель, что бы задействовать работу СЧ/ВЧ - идеальный вариант после моих тестов выявил пару с очень редким усилителем мощности и предусилителем, так же производства Франция, EMB ELECTROACOUSTIQUE MICHEL BIGOT Stereo Power Amplifier P300 + Preamplifier P5S, made in France

- в связке с данным усилительным комплексом мониторы наиболее ярко и диначмично звучат, середина и бас просто прекрасны! ВЧ конечно же делает свое дело, но будь моя воля - я бы пластиковый купол сменил на таких же размеров как и СЧ шелк... Это вообщем-то та самая связка, которая в Direct/Line работает ярко, то самое - когда темброблоки не нужны. Отдельно отмечу что в паре c SAC ICON эта пара так же ярка и замечательно звучащая...

- Hafler 1500, Alesis RA300 и около 23 усилителей просто Hi-Fi физически убивали звук данной акустики...

- мониторы прекрасны по сцене, сумашедшая детальность для своих годов-то, отличное давление НЧ (никакого бубнения и гудежа в закрытой коробке [тесты проводил как с пустыми коробками так и наполнителями: синтепон + шерсть, минеральная вата, овечья шерсть]), широкомаштабно открытые СЧ, ВЧ (про ВЧ конечно же я упоминал чуть выше)

- полное отстутвие при прослушивании "Сибилянт"

- всеядные ко стилям от Шаляпина до True Black Metal...

- акустика реагирует на подачу сигнала (то есть если никакого сигнала не идет на них - то они выключаются через 30-50 секунд, если сигнал подается -то соответственно они включаются сами, индикатором является лампочка ораньжевого цвета расположенная над НЧ динамиком, знаменующая или "рабочее состояние или режим СНА")

- вес каждой колонки примерно 22 kg!!! не смотря на свои размеры

ВИДЕО ТЕСТ:

The original 3A ANDANTE "ELECTRONIC"

The 3A ANDANTE LINEAIRE with 3A proprietary drivers in 1979

Close up view of one of the 3A servo amplifiers. Note all discrete transistors and components

The 3A ANDANTE in its original form used a 25cm SIARE driver and a compression tweeter from Fostex, as per previous models, then it evolved into the 3A ANDANTE LINEAIRE using three 3A proprietary drivers. The cabinets were still made by GUY HF, 3A being their biggest client at the time. It is nor clear who was manufacturing the amplifiers, but they ended up being very unreliable. I guess the combination of low quality, huge investment in manufacturing their own drivers and electronics, as well as the demise of some very large retailers who were the primary output for the sales of 3A speakers had a large influence on the eventual bankruptcy of the company. Interestingly enough, GUY HF was not one of the casualties of this debacle. frenchvintagehifi.co

3A closing their doors was big news at the time and coincided with the rise of JM LAB/FOCAL who became in time the largest client of GUY HF and eventually buying the business.

Another factor in the failing of the business was the plethora of models and the incessant redesign of successful speakers with new drivers and various revisions of the same models.

I have no intention to name and review all on them here but will direct you to the excellent overview put together by Jean-Marc Hauchard here: 3A Speaker family history and compilation!!!

The 3a Audiodesign andante linear is a model of "andante" series. The speaker system of 3 linear andante (3A ANDANTE LINEAIRE DE CONTROLE) is an "Acoustic Pressure Feedback" (APF) structure, a partially active box with a 125 Watt amplifier and an electronic feedback system for the woofer. The midrange and tweeter are classically supplied by the amplifier. The built-in amplifier is turned on by a signal applied. An LED indicates the operational readiness. hifi-studio

Specifications: 3a-art-et-acoustique-appliquee

• Number of ways : 3

• Acoustic principle : Acoustic pressure feedback

3A patent filed November 30, 1972 n° :

3A patent filed November 30, 1972 n° :• 72 42 542 for France

• 209 390 for Canada

• 468 868 for USA

• 53 787/74 for Japan

Synthesis

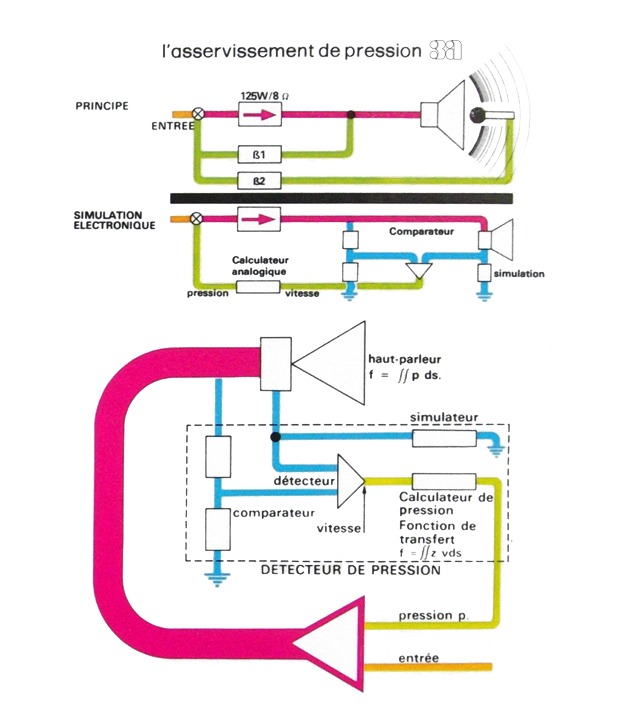

The acoustic pressure feedback (APF)

The speaker is a mechanical system which generates a sound while moving. This displacement is nonlinear (speaker's shape, suspension, non-uniform magnetic field) and the sound is distorted. So a speaker can reproduce low notes only if it's shut in a large enough « box »... In 1950, C.A. Briggs advised a brick enclosure of one cubic meter to reproduce a 16 feet organ pedal (32 Hz) !

To reduce these fantastic dimensions, engineers only found palliative (cavities, resonators, closed depreciation), but with these systems the mechanical movement of the boomer is not controlled, it is corrected. There are manufacturing of basses and not reproduction.

M. Brette and Perrin, french acousticians from the Ecole Supérieure d'Electricité (E.S.E.), were the first in 1961 to propose an acoustic pressure feedback loudspeaker, technique that was then aerospace technology. Later the company PHILIPS proposed the « Motional Feedback » (or M.F.B.) loudspeaker, based on a piezoelectric accelerometer. In 1971, Mister Daniel Dehay, Chairman of the company 3A, engineer E.S.E., succeeded to the industrial development of the acoustic pressure feedback loudspeakers.

This discovery not only removes the speaker deformations but also allow to reduces the size of the cabinets to the minimum. All mechanical movements of the driver are electronically controlled (slaved), as in the car with power brakes, power steering, in industry with machine tools programmed by computer or in aeronautics where rudders and flaps of the aircrafts are assisted.

So the basic idea was to remove the sound boxes and replace them with an amplifier that controls the movement of the driver. For that an electronic sensor records the movements of the membrane and instructs to the amplifier in the speaker to correct deformations related to the movement of the speaker. This process achieves incredible performance in miniature boxes : Linear bandwidth from 30 to 40 000 Hz in 20 dm³.

The amplifiers powering the slaved 3A loudspeakers are industrial design. All components used meet professional military standards (electrolytic or tantalum capacitors, layer resistances, integrated circuits). The circuit boards are epoxy glass, the oversized transformers are impregnated.

Each amplifier is tested at the vibrating table to test welds and avoid manufacturing defects. Finally, the electronics are made reliable by 100 hours of high power operation (60 watts), allowing debugging of components according to semiconductor technology for the space industry.

The electronics failure probability is then almost zero.

The APF system

1) - Speed bridge

The speed is detected by a Maxwell bridge system, known method for measuring the speaker characteristics.

2) - Analog calculator of slaving

This amplifier at transfer function Zm (speaker radiation impedance) was obtained experimentally by comparing the actual sound pressure in front of the speaker to the coil speed.

The vectorial composition of these two quantities allows to determine the module and phase function. A feedback electronic circuit on an amplifier with very high gain gives a very accurate picture of Zm.

The speed voltage is applied to this circuit and the output voltage is a perfect simulation of the sound pressure.

3) - The results

The amplifier necessary for the linear reproduction of 30 Hz is 125 watts. The speaker's membrane at this frequency moves about 2 cm for an electric attack power of 5 watts, corresponding nevertheless to a musical program of 100 watts.

Thus, the APF system provides to obtain from a miniature loudspeaker the same return in the bass and sub-bass than with a 15 to 20 times larger loudspeaker. Distortion is extremely low, since difficult to measure from 60 Hz. At 40 Hz, it remains below 2%. In the same volume without feedback control, a speaker would give 8% distortion.

| 1 watt | 30 Hz | 40 Hz | 50 Hz | 80 Hz | 100 Hz | 250 Hz |

| Normal loudspeaker | 18 % | 7.8 % | 5 % | 3 % | 1.9 % | 2 % |

| Same volume's slaved loudspeaker | 3 % | 1.8 % | 1.2 % | 0.9 % | 0.5 % | 0.6 % |

• Rated power : 50 W

• Built-in amplifier power : 120 W

• Sensitivity (for 1 W at 1 m) : 90 (93!!) dB

• Amplitude frequency response curve : 25 to 35 000 Hz

• Bandwidth (±2 dB) : 35 to 30 000 Hz

• Cutoff frequencies : 400 - 5000 Hz

- Tweeter : dome 19 mm 3A - T3A

- Boomer : 27 cm slaved 3A - W150AS

Origine ITT, référencé T3A à partir de 1978

Dôme Mylar transparent

Bain ferrofluide

Aimant clos

- Midrange : dome 50 mm 3A - DS50Dôme Mylar transparent

Bain ferrofluide

Aimant clos

| Caractéristiques | Unités | Valeurs |

| Puissance nominale | W | 10 |

| Puissance maximale | W | 90 |

| Bande passante | Hz | 4000-30000 |

| Niveau d'efficacité caractéristique | dB | 91 |

| Diamètre nominal hors tout | mm | 106 |

| Diamètre bobine mobile | mm | 19 |

| Diamètre ouverture baffle | mm | 75 |

| Introduction dans l'entrefer | gauss | 14 500 |

| Flux dans l'entrefer | Maxwells | 34 600 |

| Énergie magnétique du moteur | WS-1 | 0,11 |

| Facteur de force | NA-1 | 2,8 |

| Hauteur du bobinage | mm | 2 |

| Hauteur de l'entrefer | mm | 4 |

| Masse de l'aimant | g | 180 |

| Masse équipage mobile | g | - |

| Masse du haut parleur | g | 400 |

| Impédance nominale | Ω | 8 |

| Fréquence de résonance | Hz | 2000 |

| Facteur de qualité mécanique | Qms | - |

| Facteur de qualité électrique | Qes | - |

| Facteur de qualité total | Qts | - |

| Compliance de la suspension | 10-3 MN-1 | - |

| Température max de bobine mobile | C | 150 |

| Caractéristiques | Unités | Valeurs |

| Puissance nominale | W | 50 |

| Puissance maximale | W | 120 |

| Bande passante | Hz | 700-6000 |

| Niveau d'efficacité caractéristique | dB | 90 |

| Diamètre nominal hors tout | mm | 160 |

| Diamètre bobine mobile | mm | 50 |

| Diamètre ouverture baffle | mm | 125 |

| Introduction dans l'entrefer | gauss | 12 600 |

| Flux dans l'entrefer | Maxwells | 28 000 |

| Énergie magnétique du moteur | WS-1 | 0,657 |

| Facteur de force | NA-1 | 7,9 |

| Hauteur du bobinage | mm | 4 |

| Hauteur de l'entrefer | mm | 5 |

| Masse de l'aimant | g | 850 |

| Masse équipage mobile | g | 3,2 |

| Masse du haut parleur | g | 1 960 |

| Impédance nominale | Ω | 8 |

| Fréquence de résonance | Hz | 380 |

| Facteur de qualité mécanique | Qms | 5,1 |

| Facteur de qualité électrique | Qes | 1,7 |

| Facteur de qualité total | Qts | 0,57 |

| Compliance de la suspension | 10-3 MN-1 | - |

| Température max de bobine mobile | C | 180 |

| Caractéristiques | Unités | Valeurs |

| Puissance nominale | W | 150 |

| Puissance maximale | W | 200 |

| Bande passante | Hz | 25-2000 |

| Niveau d'efficacité caractéristique | dB | 93 |

| Diamètre nominal hors tout | mm | 295 |

| Diamètre bobine mobile | mm | 38 |

| Diamètre ouverture baffle | mm | 234 |

| Introduction dans l'entrefer | gauss | 14 200 |

| Flux dans l'entrefer | Maxwells | 102 000 |

| Énergie magnétique du moteur | WS-1 | 0,620 |

| Facteur de force | NA-1 | 11,87 |

| Hauteur du bobinage | mm | 14 |

| Hauteur de l'entrefer | mm | 6 |

| Masse de l'aimant | g | 850 |

| Masse équipage mobile | g | 18 |

| Masse du haut parleur | g | 2 800 |

| Impédance nominale | Ω | 5 |

| Fréquence de résonance | Hz | 40 |

| Facteur de qualité mécanique | Qms | 3,43 |

| Facteur de qualité électrique | Qes | 1,77 |

| Facteur de qualité total | Qts | 0,42 |

| Compliance de la suspension | 10-3 MN-1 | - |

| Température max de bobine mobile | C | 180 |

• Dimensions (H x W x D) : 46 x 30 x 21 cm

• Acoustic volume : 16 dm3

"Control Room" setting of the low register by 4-position switch on the back :

• A : On the floor in the corner of the room

• B : Elevated position in the corner of the room > 50 cm

• C : On the floor along a wall

• D : Elevated position along a wall

Daniel Dehay founded in 1971 the company 3A ( "3A" is the abbreviation for Applied Acoustic Arts) in France. A small company, today. In Ontario Canada that deals with the construction of loudspeakers But basically extends the 3A history back to the late 1950s. Daniel Dehay was around twenty years loudspeaker developers in the known French loudspeaker manufacturer Cabasse. Dehay preference has always been minimalist design and construction principles.

The cabinet consists of 19 mm MDF with internal bracing and is painted with hard lacquer.

Link: 3a-art-et-acoustique-appliquee

![Infrequent Sound [sex.tex] technology](https://blogger.googleusercontent.com/img/b/R29vZ2xl/AVvXsEgYjsR0yBjx1asXd9RcHaPAqGmfjf3vlwTTJNdkEd5mSGJ9rJWByMDPi2EsfWrHP7UxXHcPrZNpbPrcnBAsAdc8IC2laTcEEtBPU0Sn15W8ej00BbKglgMk3POjsvF9FbhoZXwGGlMdLywV/s1328/1+2.jpg)

Комментариев нет:

Отправить комментарий